|

|

|

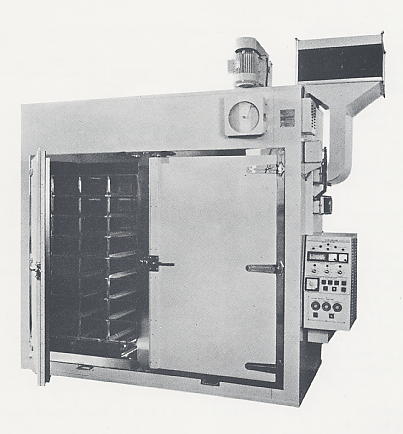

STERILISING OVEN

Technical features

Temperature range between +5°C above ambient and +230°C

Outer case in epoxy painted steel plate with acid and rust-proof ground

Inner chamber in stainless steel plate

Two- shutter and double walled door with silicone rubber gaskets

Thermo-insulation via thick rock wool panels

Electric heating provided by stainless steel sheathed flyer resistors

Fan-forced air circulation through specific fan suitable for high temperature

Group of fan-resistors, placed in the lower part for easy inspection

Graduated air re-cycle through shutters

Front control panel housing

Digital thermostat with microprocessor allowing P.I.D. auto-tuning control

Alarm light for cycle ending

Safety thermostat with indicator lamp

Digital timer for cycle setting

Line switch

Timer switch

Safety fuses

Model 3672

External dimensions (WxDxH) 200x80x240 cm

Internal dimensions (WxDxH) 140x60x180 cm

Capacity litres 1500

Weight KGs 450

Power rating 15 kW

Three-phase V380 + N + Ground

OPTIONS:

- daily/weekly temperature recorder

- temperature above ambient up to +300°C (Model 3673 )

Different dimensions are available upon request

STERILISING OVEN

Double door oven, specifically designed for pharmaceutical labs, suitable to be accommodated in places between sterile and pre-sterile rooms.

Technical features:

- Temperature range above ambient + 5°C up to 250°C

- Outer case and internal chamber in stainless steel according to AISI 304

- Stainless steel grid shelves, ladder-rack type, to improve air flow and provide an even more

temperature distribution within the oven

- Glass fibre insulation

- Double door featuring chromate brass hinges and closing onto silicone rubber gaskets

- Manual or automatic door lock with visual indicator lamp

- Double chamber for forced circulation of hot air via electric fan suitable for high

temperature

- Heating via battery of flyer resistors in stainless steel

Side Control Panel housing:

- Digital thermostat with microprocessor allowing P.I.D. auto-tuning control

- Alarm light for cycle ending

- Over-temperature safety thermostat

- Multi-scale timer

- Line switch

- Heater switch

- Safety fuses

- Acoustic and visual alarm light signalling cycle ending

380 V + N + Ground

Different dimensions are available upon request

Electric supply according to CEI 62-25

STERILISING OVEN FOR DRYING AND COOLING

Technical features:

Inner chamber:

18/8 AISI 304 stainless steel or 18/8/2 AISI 316 upon request

Outer case:

in steel plate painted in light grey colour with blue shutters (different colours are available

upon request)

Doors:

double walled doors with silicone rubber gaskets. Device preventing the opening of the two doors at the same time

Thermo-insulation:

rock wool panels having an average thickness of 10 cm.

Fan:

centrifugal fan with 18/8 steel impeller, suitable for high temperature

Heating battery:

flyer elements with low surface density, made of 18/8 AISI 304 stainless steel

Control panel:

low tension auxiliary circuits according to CEI regulations; built-in converters; safety fuses for circuit protection

Filter with 99,99% efficiency

Daily/weekly temperature recorder available upon request

Runners

18/8 AISI 304 stainless steel. Non-tip edges for ease of cleaning

Under-runners:

painted steel. Adjustable revolving wheels in rubber. Automatic clasping devices .

Electric system according to CEI 62-25